Computer Simulation of High Speed Impact

David C. Haeberle

ESM 4984

11/2/98

Material Parameters - 7039 Aluminum

A = 336.46 MPa

B = 342.66 MPa

C = 0.01

n = 0.41

m = 0.6

r

= 2,770 kg/m3q

m = 604 oCK = 81 GPa

m

= 28 GPac = 875 J/kgoC

Input File for Finite Element Analysis

Introduction

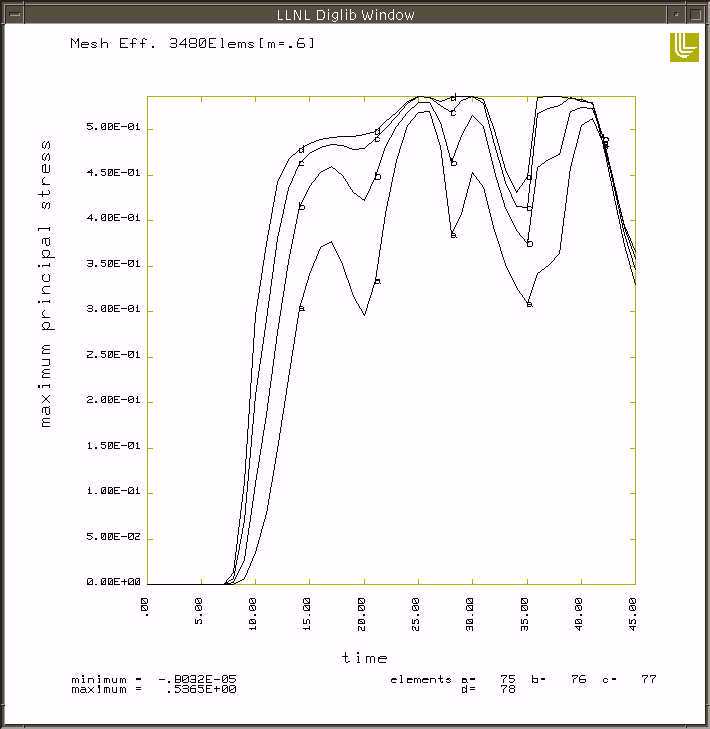

The material parameters above were inserted into a prepared finite element code to evaluate the effects of high-speed impact on the material. Two different types of failure are possible, plastic and brittle. The goal of this exercise was to determine impact times for plastic and brittle failures at 10, 20, 30, 40, 50, and 60 m/s. The results are plotted to determine the critical speed where the failure mode switches from brittle to plastic. Principal stresses were evaluated to determine tbrittle and Von Mises stresses were evaluated to determine tplastic. tbrittle is defined as the time when the principal stress , s, reaches a certain value given by the following equation.

s = 2[

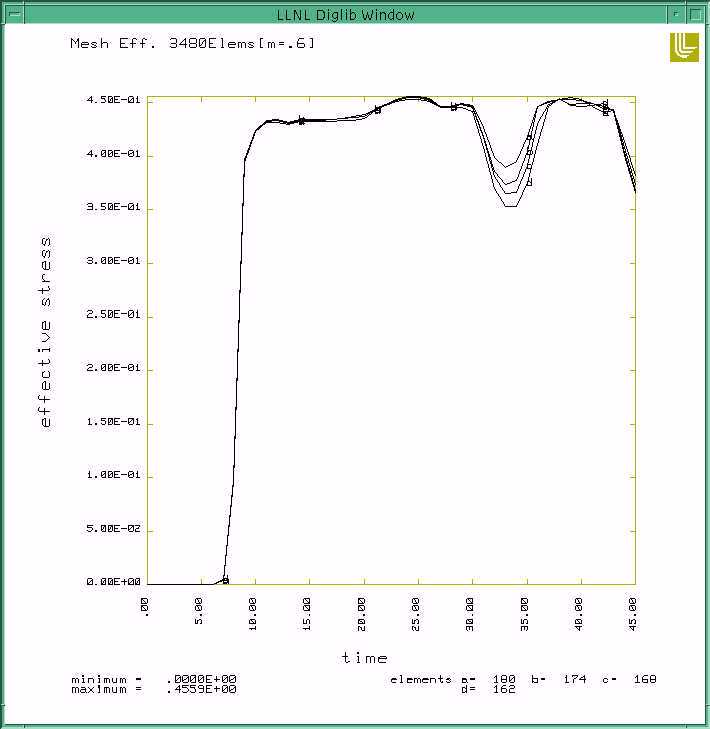

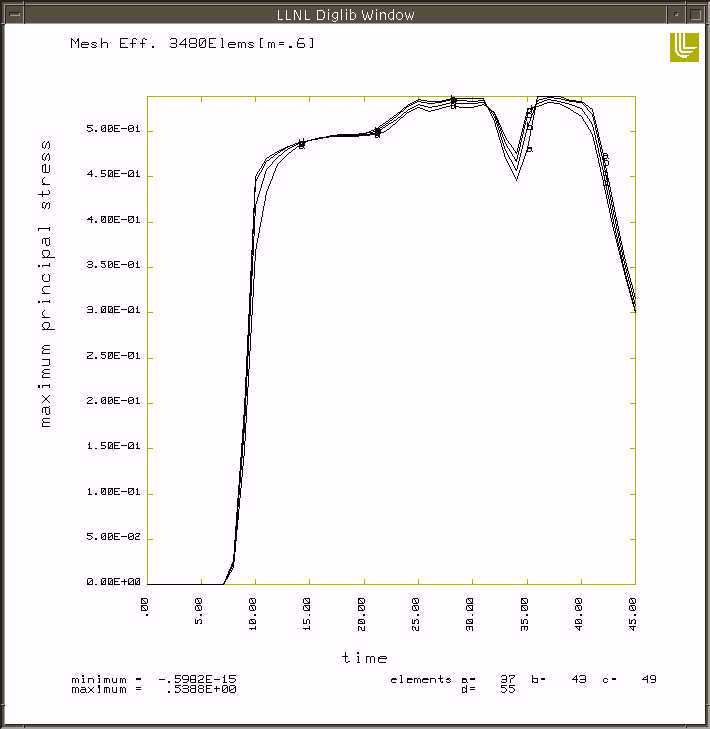

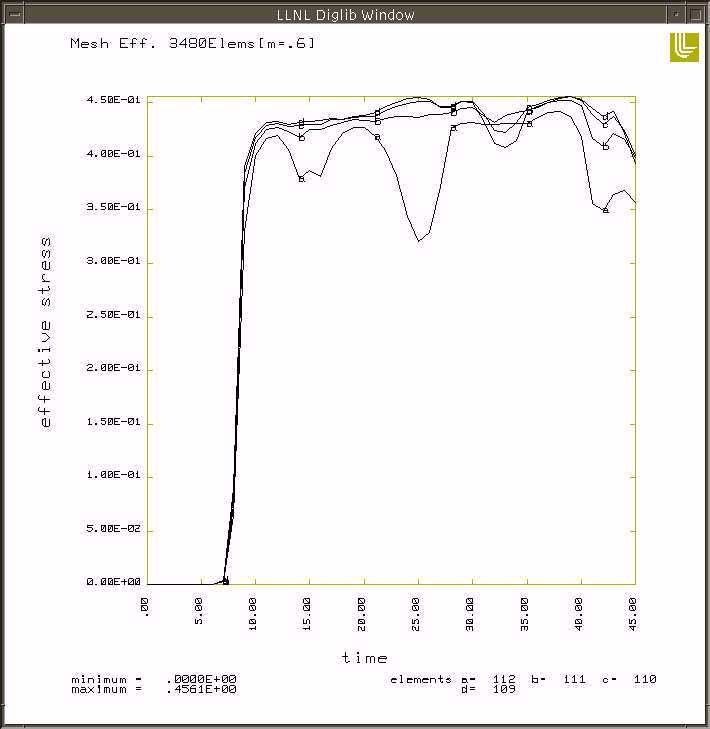

A + B(0.002)n]7039 Aluminum produces a value of 730 MPa for s. tplastic is defined as the time where the Von Mises stress drops below 90% of its maximum value. The above information is determined from the graphical output of the FEA code.

Results

At the impact speeds given, 7039 Aluminum did not reach the estimated s, thus an estimate of 500 MPa was made for finding tbrittle . The following is the graph of the brittle and ductile failure times versus impact speed.

The following example plots are the four output plots for an impact speed of 10 m/s.

Principal Stress - Elements 75, 76, 77, 78

Principal Stress - Elements 37, 43, 49, 55

Von Mises Stress - Elements 109, 110, 111, 112

Von Mises Stress - Elements 162, 168, 174, 180